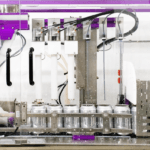

Accessories for your

beverage Canning line

We offer a number of different canning line accessories to make packaging your craft product easier and more efficient. Choose from labelers, depalletizers, date coders and other canning accessories that will improve efficiency and help your brand stand out from the craft beverage crowd.

"We routinely have near perfect yields on our canning runs, day in and day out."

"What sets Twin Monkeys apart and far above the rest is not only the quality and reliability of the equipment but the talent, character and care of their support team."

“I am really happy with the operation of the machine and the support from the guys in the US has been great.”

"I cannot recommend Twin Monkeys enough!”

Previous

Next