THE MANCOS COUNTER PRESSURE (5-8 CANS/MIN)

Counter Pressure Fill Technology

COUNTER PRESSURE FILL TECHNOLOGY

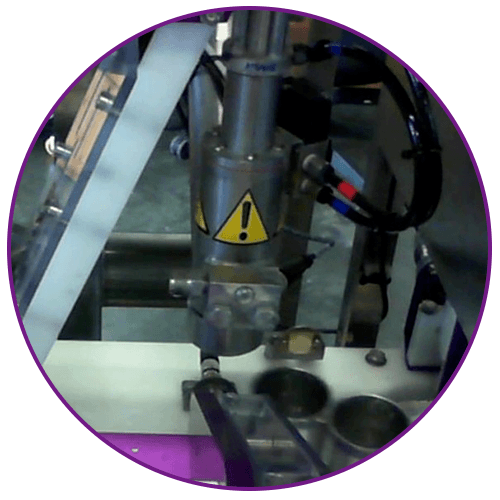

The Mancos CP is a canning machine that uses counter pressure fill technology. This canning machine is perfect for packaging high carbonation and high temperature products in cans. The counter pressure fill technology uses product pressure regulation during the fill cycle to reduce breakout of CO2 and control foam generation.

- Ideal for High Carbonation Products

- High temperature Products

- Gain More Flexibility

- Counterfill Pressure Fill Technology

- Control Foam Generation

- Reduce breakout of CO2

Features & Specs

Capabilities

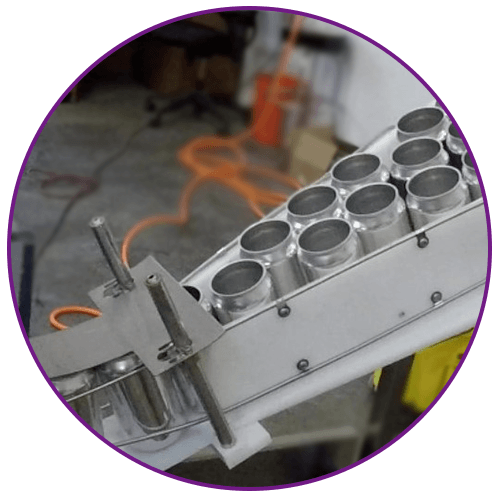

- Fully automated purge, counter pressure fill, lid apply, seam

- Adjustable timers for all system functions

- CIP/SIP for fill system

Equipped with

- Fully integrated cart and drip tray.

- Lid applicator with CO2 blanket generator

- Intuitive operator color touch screen with QR code support manual access

- Washdown systems for easy cleaning

- Pre-Rinse mechanism

5-Step Oxygen Reduction

- Closed fill tubes that do not re-acquire air between fill cycles

- Pre-fill purge station that clears air out prior to fills

- Short paths from fill to seam

- CO2 blanket generator when lids are placed on foam

- Dial-in foam/fill levels for individual fill head control

Utilities

| Power: | 120V or 230V 1-phase (50/60hz) | ||

| Controls Air: | 90 psi 1 cfm of clean, dry air | ||

| CO2: | 20 psi .5 cfm of CO2 |

Specs

- Throughput: 5-8 cans per minute

- Can Sizes: Slim, Sleek, Standard

- Lids: 200, 202, 204, 206 sizes in all styles

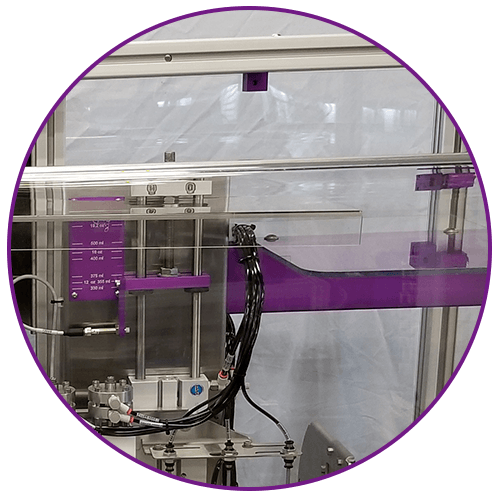

- Dimensions: 49” LG x 38” WD x 62” H, 34.5” deck height

- Weight: 490 lbs

- Construction: Stainless steel, anodized aluminum, food grade acetal

- Power: Has both 120V and 240V options.

- CO2: .5 CFM @ 25 PSI

- Air (Operating): 2.1 CFM clean dry air @ 90 PSI

- Air (MAX): 3.2 CFM clean dry air @ 90 PSI

- Beverage Capability: Beer, Wine, Coffee, Kombucha, RTD, Soda, Water and Juice, THC Infused, CBD Infused

customize your setup

Like all of our commercial canning systems, The Mancos CP is fully customizable. Here are a few optional add-ons that can make this canning machine as powerful and as advanced as any inline canning machine you will find on the market.

Looking for something specific? Contact us directly to discuss your options.

Automatic infeed option

a. Infeed Shelf b. Twist Rinse c. Infeed Chute

Integrated Liquid Nitrogen Dosing

Add a drop of LN2 to each can just before lid apply.

Full Guarding Cage

Full-Lexan guarding for canning system to meet regulations in Europe.

Add the Advanced Tech Pack

Take The Mancos CP to the next level by adding the Advanced Tech Pack. This package includes all of these add-ons:

- Automated Tank Pressure Controller: Maintains beverage tank pressure for perfect fills.

- Post-Seam Rinse/Dry Module: Rinses cans prior to packaging.

- Lid Check Sensor: Lid sensor checks for a lid on a can before seaming.

If no lid is detected it will not seam. - Index and Seamer Sensing: Additional sensors added to Index and

Seamer systems to better monitor real time positioning and suggest

maintenance intervention if axes slow down.

explore Financing options

Free up working capital | Gain tax advantages | Match payments to cash flow