THE #1 CUSTOM CONFIGURED CANNING SYSTEM ON THE MARKET TODAY.

Twin Monkeys engineers canning systems for all craft beverage makers’ needs. We offer pallet-to-pallet beverage packaging solutions and can customize any canning system to fit your needs. We understand the hard work you put in to make the beverages for your customers, and we want to make it easy for you to package your product.

Twin Monkeys Canning Systems

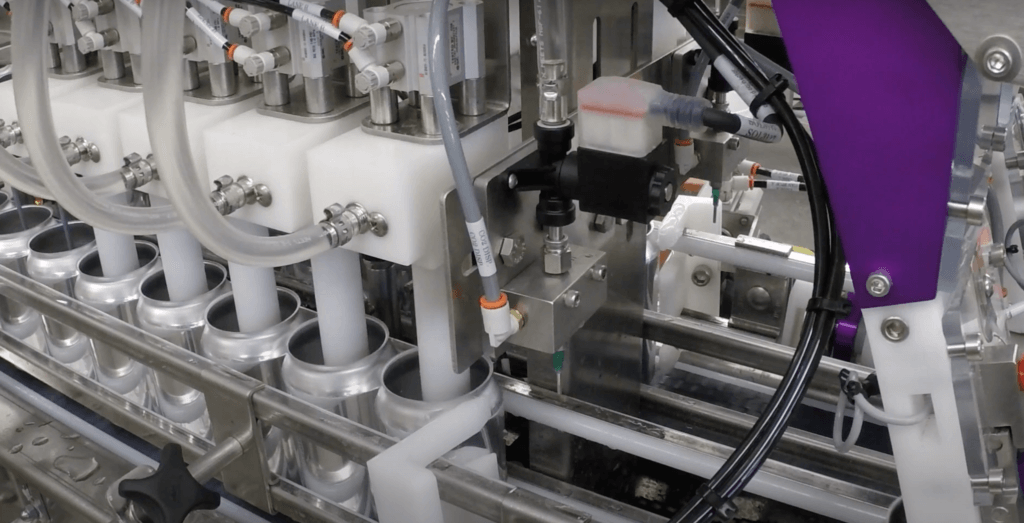

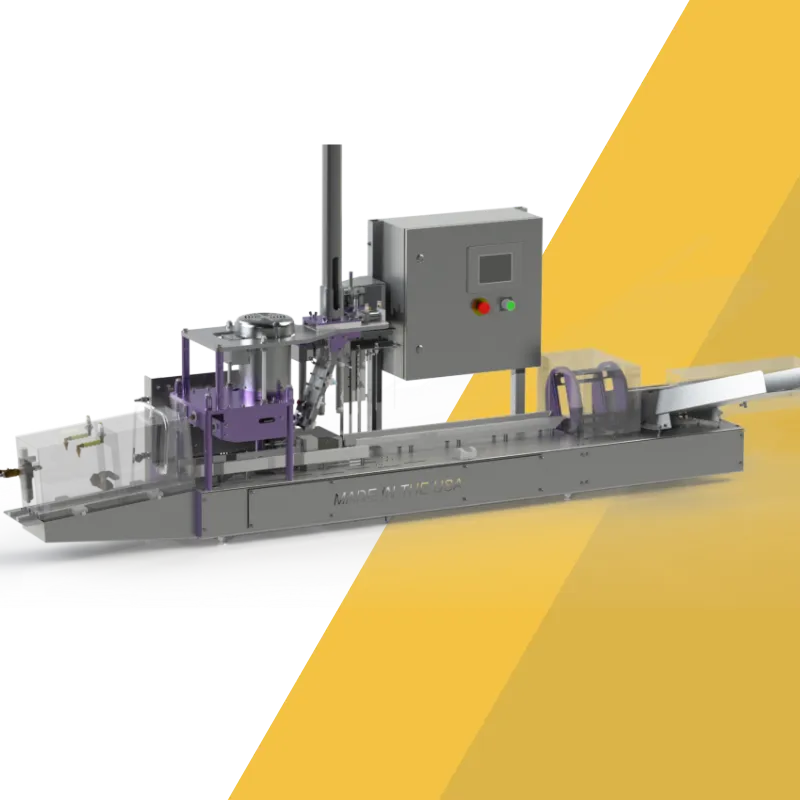

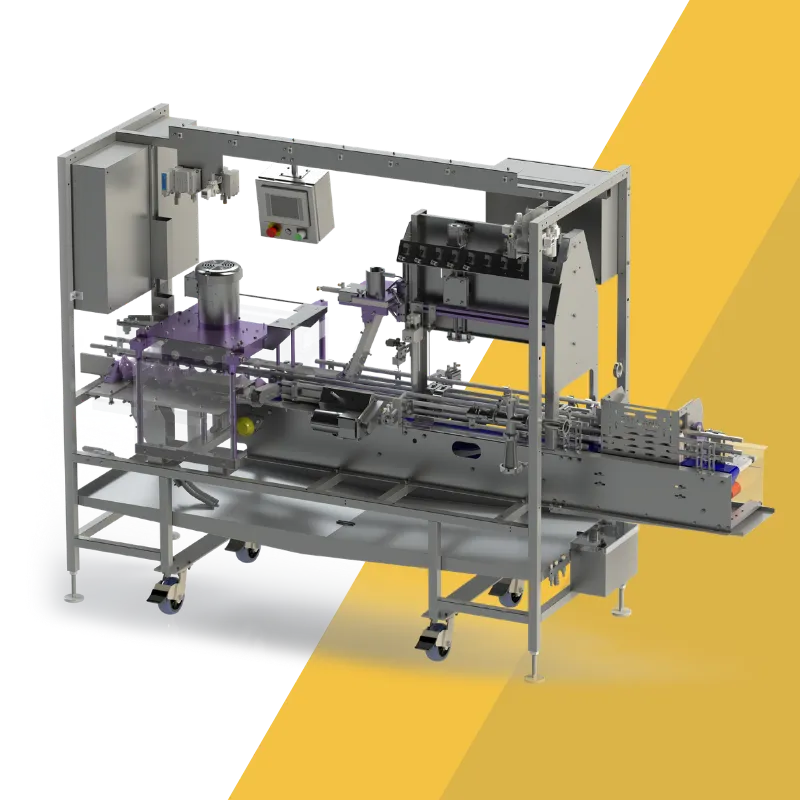

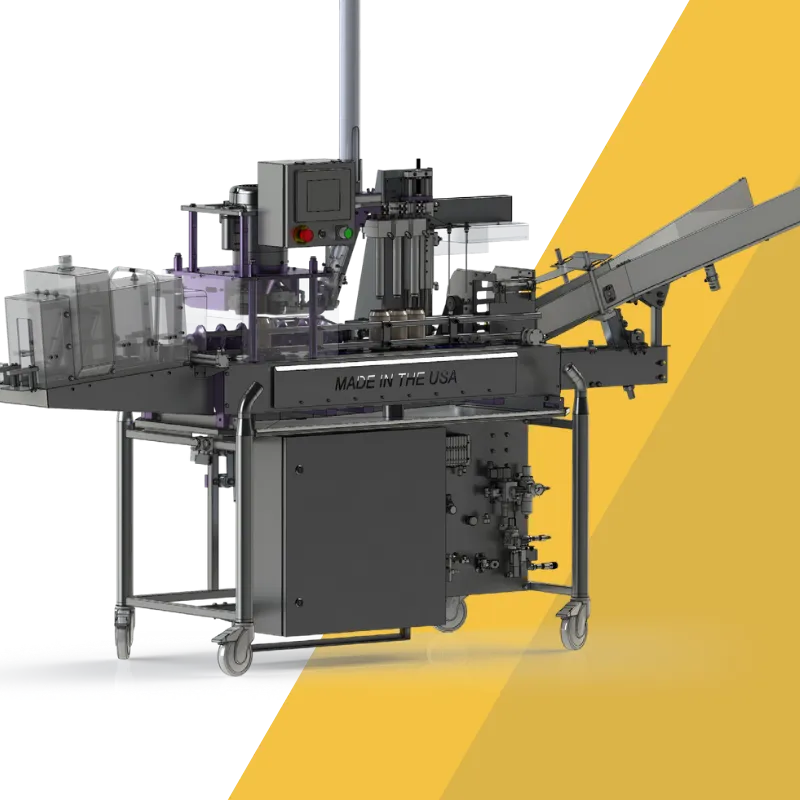

Our canning machines are highly customizable and Made in the USA. They are modular, easy to use, affordable, and designed to grow with your needs as a craft beverage maker. Let’s work together to find the best solution for your canning needs and the most efficient way to bring your craft products to market.

Twin Monkeys canning systems are designed to be custom configured to each customer’s needs. Our modular designs make these systems ideal for your growing craft business.

Need multiple can heights or diameters? Not a problem! Our canning systems can handle multiple can heights and can diameters. Change between sizes with ease.

Less waste. More filling. Twin Monkeys designs systems that automate processes, reduce operator dependence and minimize waste during the canning process.

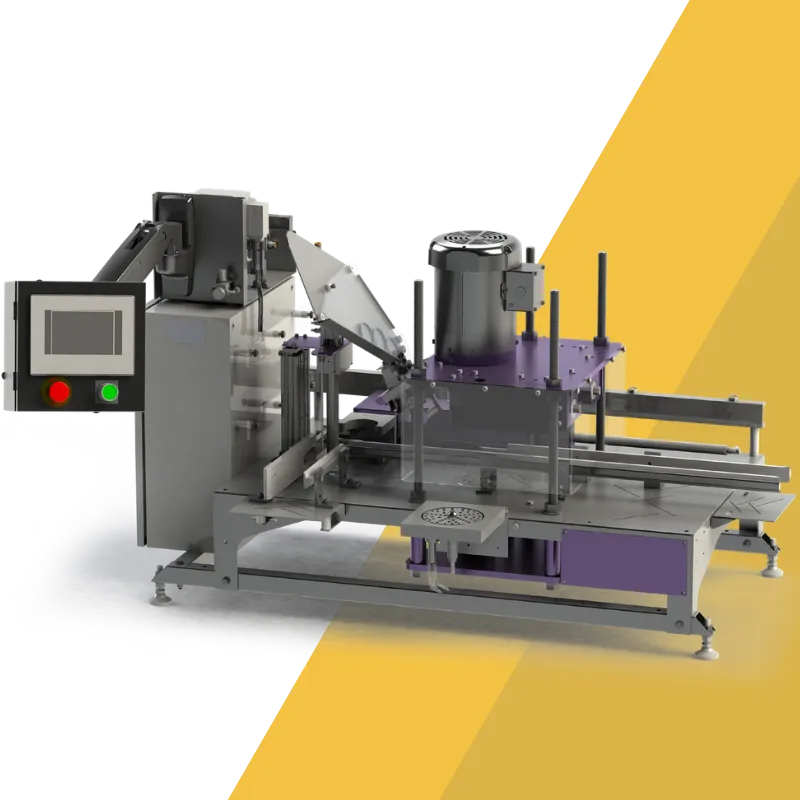

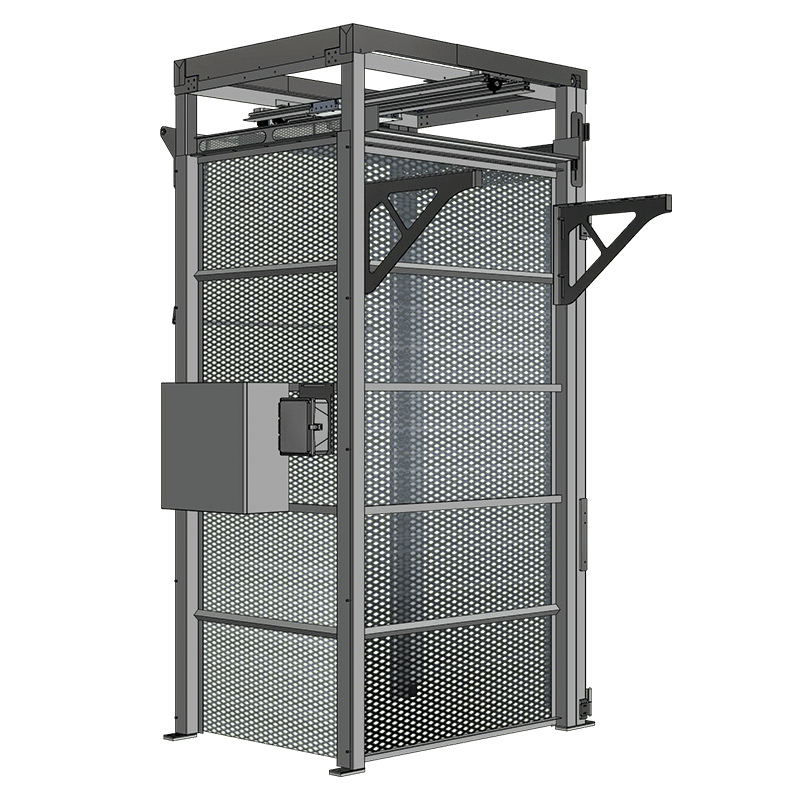

AUXILIARY EQUIPMENT

Complete canning systems for every craft beverage.

A complete beer canning line or other beverage canning line often includes accessory equipment that make canning days more efficient. Choose from date coders, depalletizers, can labeling machines, feed and accumulation tables, twist rinsers and more. Take a look at all of our canning accessories and let us help you determine what is right for you. If you are looking for something specific, let us know. We are happy to walk you through all of your options.

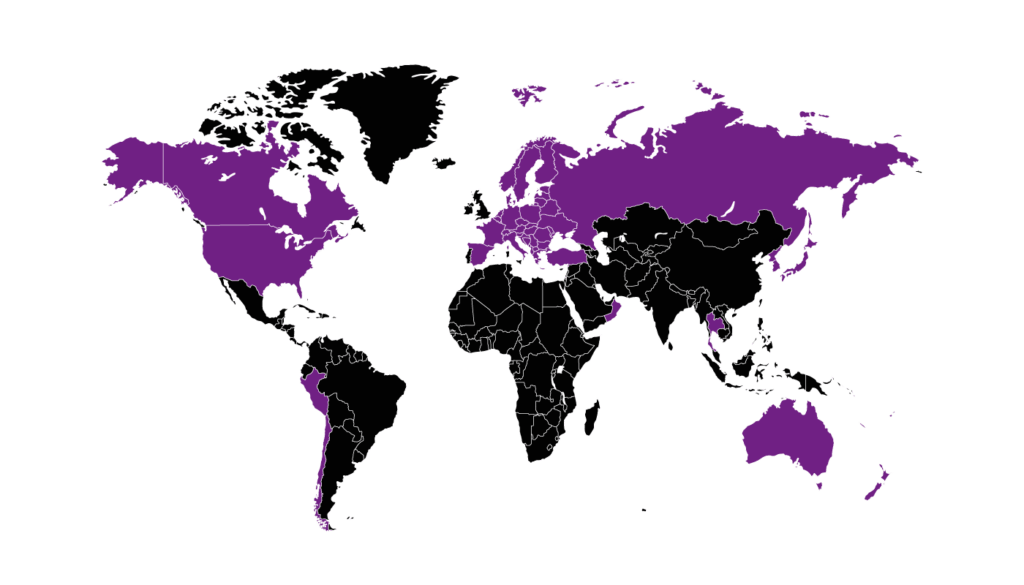

Global Canning Solutions

Our canning systems are used by craft brewers around the world. Find a system near you.

FOLLOW US @TWINMONKEYSBEVERAGESYSTEMS

finance your setup

Free up working capital | Gain tax advantages | Match payments to cash flow