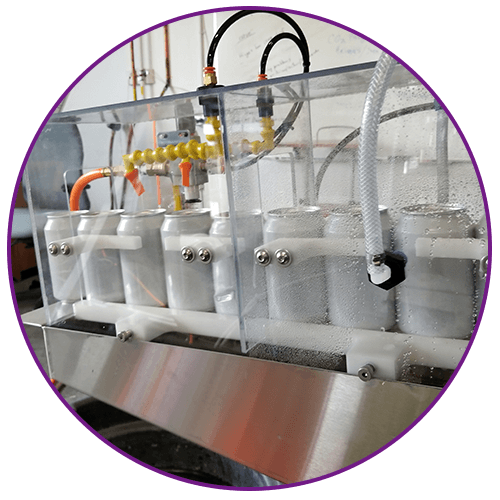

THE GUNNISON CANNER

(25-30 CANS/MIN)

Ultra-compact and highly versatile.

FAST, REPEATABLE, EASY TO MAINTAIN

Our most popular line, the Gunnison canning system can produce 25-30 cans per minute. Its ultra-compact footprint has made it popular with mobile canning operations, as well as small and medium size beverage producers with limited space. Its versatility and quick change over for additional can diameters allows businesses producing more than one can size to maximize efficiency. With a wide array of infeed and outfeed options, this canning machine can be custom configured.

- Compact Footprint

- Patented cam-less wedge seamer

- DO pick up as low as 20 PPB

- Integrated Automated Pressure Control

- Increased Maneuverability

- Easily change between can diameters

Features & Specs

Capabilities

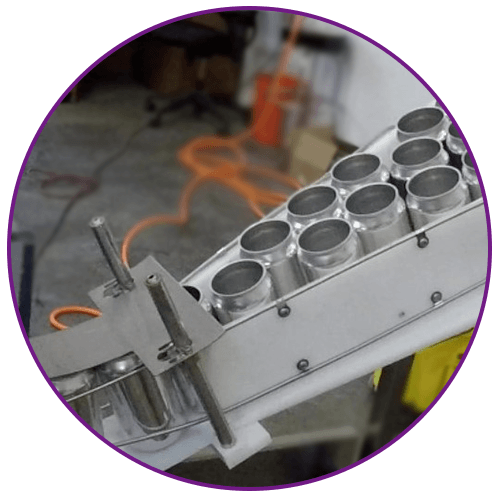

- Patented Seamer Technology

- Lid applicator with CO2 blanket generator

- TPO Pickup as low as 20ppb

- Integrated Automated Tank Pressure Control

- Mobile friendly with locking casters on a movable cart

- Quick change out between can diameters

5-Step Oxygen Reduction

- Closed fill tubes that do not re-acquire air between fill cycles

- Pre-fill purge station that clears air out prior to fills

- Short paths from fill to seam

- CO2 blanket generator when lids are placed on foam

- Dial-in foam/fill levels for individual fill head control

Utilities

| Power: | 120V or 230V 1-phase (50/60hz) | ||

| Controls Air: | 90 psi 1.5 cfm of clean, dry air | ||

| CO2: | 20 psi .5 cfm of CO2 |

Specs

- Dimensions: 52” L (1320mm) X 26” D (660mm) X 60” H (1520mm)

- Case Per Minute: 25-30

- Weight: 450 lbs. (204 kg)

- SCFM (AIR): 90 psi 1.5 cfm of clean, dry air

- Can Options: Slim, Sleek, Standard

- Beverages capable: Beer, Wine, Coffee, Kombucha, RTD, Soda, Water, Juice, THC infused, CBD Infused

customize your setup

Like all of our commercial canning systems, The Gunnison is fully customizable. Here are a few optional add-ons that can make this canning machine as powerful and as advanced as any canning machine you will find on the market.

Looking for something specific? Contact us directly to discuss your options.

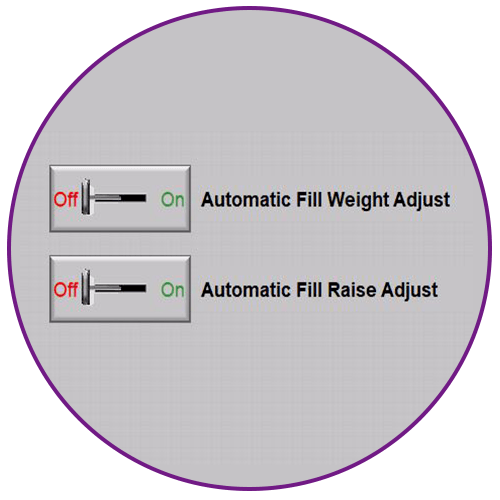

Auto Weigh/Fill Adjust/Reject Option

Let the canning machine automatically adjust the fill levels and reject low weight cans, ensuring proper fill amounts.

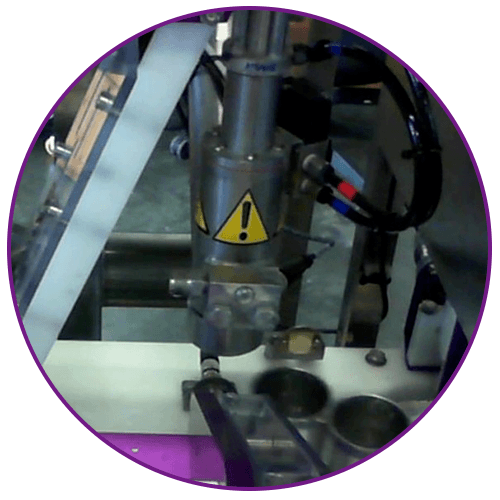

Integrated Liquid Nitrogen Dosing

Add a drop of LN2 to each can just before lid apply.

Integrated Date Coding

Full Guarding Cage

Full-Lexan guarding for canning system to meet regulations in Europe.

Infeed Options

a. Infeed Shelf

b. Twist Rinse

c. Infeed Chute

Final Rinse/Dry

Rinse/dry cans.

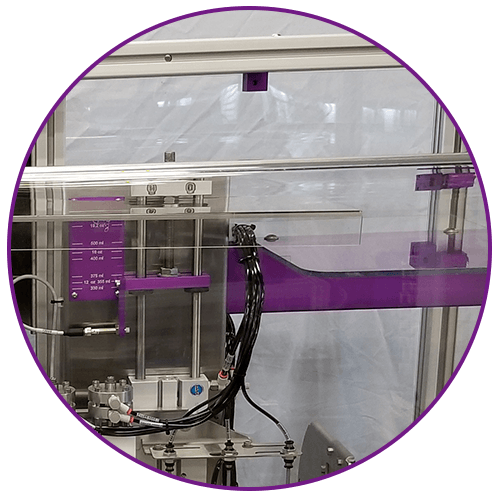

Add the Advanced Tech Pack

Take The Gunnison canner to the next level by adding the Advanced Tech Pack. This package includes all of these add-ons:

- Automated Tank Pressure Controller: Maintains beverage tank pressure for perfect fills.

- Post-Seam Rinse/Dry Module: Rinses cans prior to packaging.

- Lid Check Sensor: Lid sensor checks for a lid on a can before seaming.

If no lid is detected it will not seam. - Index and Seamer Sensing: Additional sensors added to Index and

Seamer systems to better monitor real time positioning and suggest

maintenance intervention if axes slow down.

explore Financing options

Free up working capital | Gain tax advantages | Match payments to cash flow