THE MANCOS

(UP TO 12 CANS/MIN)

Automated nano canning machine.

HIGH QUALITY NANO CANNING EXPERIENCE

The Mancos canning line delivers a high-quality packaging experience for any craft beverage. No other canning system (of any size) can deliver on as many varying can diameters, such as slim, sleek, and standard on one single machine.

- Ideal for nano canning

- Compact Tabletop Footprint

- Gain More Flexibility

- Easily change can sizes

- Adjustable Timers

- Automated purge, fill, lid apply, seam

- CIP/SIP for fill system

Features & Specs

Capabilities

- Available can-styles: Sleek, slim, and standard cans

- Tiny tabletop footprint

- Fully automated purge, fill, lid apply, seam

- Adjustable timers for all system functions

- CIP/SIP for fill system

- TPO pickup as low as 20 PPB

Equipped with

- Patented Seamer Technology

- Lid applicator with CO2 blanket generator

- Intuitive operator color touch screen with QR code support manual access

- Washdown systems for easy cleaning

- Pre-Rinse mechanism

5-Step Oxygen Reduction

- Closed fill tubes that do not re-acquire air between fill cycles

- Pre-fill purge station that clears air out prior to fills

- Short paths from fill to seam

- CO2 blanket generator when lids are placed on foam

- Dial-in foam/fill levels for individual fill head control

Utilities

| Power: | 120V or 230V 1-phase (50/60hz) | ||

| Controls Air: | 90 psi 1 cfm of clean, dry air | ||

| CO2: | 20 psi .5 cfm of CO2 |

Specs

- Throughput: Up to 12 cans/minute, depending on can size

- Can Sizes: Slim, Sleek, and Standard

- Dimensions: 52”l x 32”d x 33”h (1320mm x 838mm x 762mm)

- Weight: 250 lbs (113 kg)

- Construction: 304 stainless steel and anodized aluminum

customize your setup

Like all of our canning lines, The Mancos is fully customizable. Here are a few optional add-ons that can make this setup as powerful and as advanced as any nano canning machine you will find on the market.

Looking for something specific? Contact us directly to discuss your options.

Integrated Liquid Nitrogen Dosing

Add a drop of LN2 to each can just before lid apply.

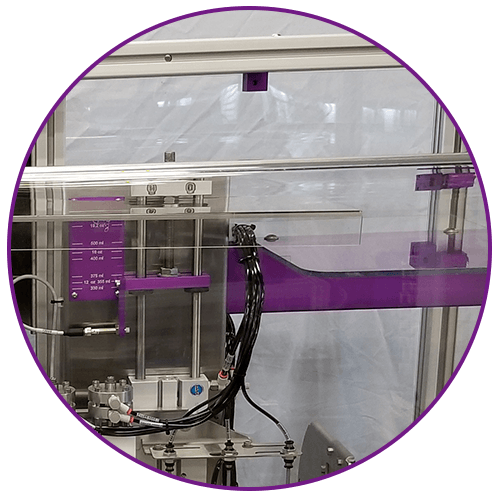

Full Guarding Cage

Full-Lexan guarding for canning system to meet regulations in Europe.

Add the Advanced Tech Pack

- Automated Tank Pressure Controller to maintain beverage pressure for perfect fills

- Automated Fobber to add the perfect foam to each can for advanced oxygen reduction

- Post-Seam Rinse/Dry Module to clean the cans prior to packaging

- Automated Fill Raise to determine the precise time to withdraw the filler

- Lid Sensor: Lid sensor checks for a lid on a can before seaming. If no lid is detected it will not seam.

explore Financing options

Free up working capital | Gain tax advantages | Match payments to cash flow